Explore Productsended

PATIKIL 1mm Drill Bit, M42 8% Cobalt High-Speed Steel Jobber Straight Shank 135° Titanium Nitride (TiN) Coated for Hard Metal Stainless Steel - 5 Pack

PATIKIL 1mm Drill Bit, M42 8% Cobalt High-Speed Steel Jobber Straight Shank 135° Titanium Nitride (TiN) Coated for Hard Metal Stainless Steel - 5 Pack

Item Details

Pickup Location

4031 Market Center Dr Suite 303

North Las Vegas, NV, 89030

Quality

Used

Functional

No Damage

No Assembly Needed

In Package

No Missing Parts

Estimated Retail Price

$7.70

Buyers Premium

15%

Inventory Number

1048669208

Additional Details from the Manufacturer

This item information is coming from the manufacturer. Some of the details may vary from the Nellis Auction listing. Please check the Quality Rating and Notes for information specific to this listing

brand

PATIKILsize

1mmMore features

- PACKING LIST: 5 packs of drill bits in 1mm(0.04 inch ≈ 1/25 inch) cutting diameter, 10mm/0.39 inch flute length, 34mm/1.34 inch overall length, 135-degree split point

- FEATURE: M42 high-speed steel is formulated with a high 8% cobalt, high hardness and wear resistance, especially suitable for processing hard materials, excellent heat resistance, suitable for high-speed cutting. The titanium nitride (tin) coated can prevent further oxidation or corrosion of the drill bits and extend the service life.

- APPLICATION: The M42 material drill bit has a high 8% cobalt content, mainly used in demanding professional drilling operations, making it suitable for processing medium-high hard metals. It is suitable for drilling various materials, including stainless steel, iron, aluminum, copper, plastics, and wood.

- NOTE: High cobalt HSS typically has a higher number of drilling times than M2 HSS and M35 HSS under the same conditions, potentially thousands or more. This significantly increases machining efficiency and reduces costs, especially when machining difficult materials.

- INSTRUCTION: The twist drill should be at a 90° angle to the workpiece. When drilling different materials, the drilling speed needs to be adjusted. The harder the material, the lower the drilling speed should be. Adjusting the speed can improve cutting efficiency, extend tool life, and reduce material damage.

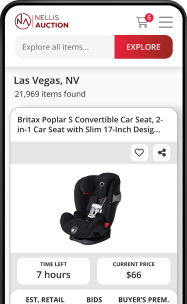

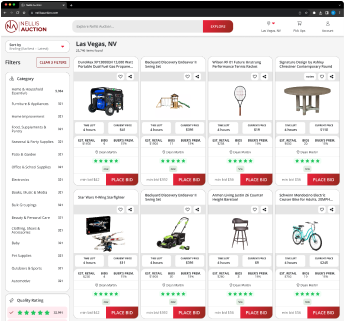

See the deals

Get in on the action, thousands of new items added daily. Bid and win!

Start bidding now