Explore Productsended

Brake Line Flaring Tool Kit for 45 Degree Single, Double and Bubble Flares, Brake Line and Tubing Flaring Tool for 3/16", 1/4", 5/16", 3/8" and 4.75mm Steel Copper Metal Tubing, Brake Flaring Tools

Brake Line Flaring Tool Kit for 45 Degree Single, Double and Bubble Flares, Brake Line and Tubing Flaring Tool for 3/16", 1/4", 5/16", 3/8" and 4.75mm Steel Copper Metal Tubing, Brake Flaring Tools

Notes

USED ////

Item Details

Seller

Nellis Auction

Pickup Location

4031 Market Center Dr Suite 303

North Las Vegas, NV, 89030

Quality

Used

Functional

No Damage

No Assembly Needed

In Package

No Missing Parts

Estimated Retail Price

$84.73

Buyers Premium

15%

Inventory Number

1048016817

Found in

Additional Details from the Manufacturer

This item information is coming from the manufacturer. Some of the details may vary from the Nellis Auction listing. Please check the Quality Rating and Notes for information specific to this listing

brand

YuesstlooMore features

- The Multi-Purpose Flaring Tool is an all-in-one brake line flaring device that efficiently creates 45-degree single, double, and bubble brake flares on 304 stainless steel, steel, and soft metal tubing in a short period of time. The excellent quality and accuracy of the flares produced by this tool prevents subsequent leaks in hydraulic or brake systems, making it an indispensable brake flaring tool for DIY enthusiasts and professional mechanics.

- Wide applicability: The flaring tool can fit a wide range of lines with diameters of 3/16", 1/4", 5/16", 3/8", and 4.75-millimeter, covering applications such as automotive brake lines, transmission cooler lines, and fuel delivery lines.

- Professional-grade brake flaring tool kit: carefully crafted from high-quality steel and heat-treated and oxidation-strengthened to ensure that the tools have extreme hardness and excellent durability to withstand wear and tear in long-term use.

- Tips for Use: Prior to the flaring operation, deburr the inside and outside of the tubing to ensure that metal shavings and contaminants are removed from the inside and outside of the tubing. Then, apply a small amount of anti-seize to the end of the cut tubing to prevent problems when extruding.

- In addition, a small amount of oil can be added to the flare cone (OP.1 and OP.2). Finally, take care to place the appropriate fittings at the end of the tube so that the flared end faces outward

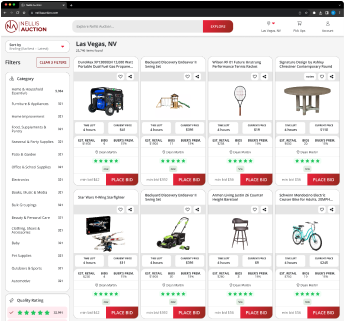

See the deals

Get in on the action, thousands of new items added daily. Bid and win!

Start bidding now